Equipment for oil terminals

Hoses

Connect Couplings

Belts

Rubber, non asbestos sheets, sealing materials

Molded products

Conveyor belts and conveyor components

Technical rubber

/

/

/

/

LONG REACH TOP LOADING ARM with VAPOUR RECOVERY CONE Series 1201

The 1201 series top loading arms are used to fill tankers from above where it is necessary to have a wide range of action available. This allows maximum covering of the loading points. In addition, the vapor recovery version permits the return of vapors in the line through a dedicated pipe.

Components (standard configuration)

* Right-hand layout, bottom inlet, ANSI 150 connecting flange

* Carbon steel high resistance swivel style F-20 with carbon steel boom pipe

* Double swing base swivel style F-50: It is used for horizontal and vertical rotations. It is made with two swivel joints with double ball bearing rows and FKM seals.

* Torsion Spring Balancing unit: It is used to balance the loading arm.

* Loading Valve “ stay open ” or ” Hold Open ” type opens and closes flow and has a double stage easy opening and adjustable valve closure velocity, in relation to specific pressure and viscosity of the product being loaded.

* Secondary Pipe made of aluminium alloy TTMA flanged

* Valve Remote Control

* Drop Pipe Swivel style F-40: It is used to keep the drop pipe in vertical position. It is supplied with a handle to facilitate the movement of the arm.

* Drop Pipe made of aluminium alloy, TTMA flanged which holds an aluminium Vapour recovery cone covered with vulcanized rubber resistant to aromatics and high temperatures. (The drop pipe can have deflector or end pipe)

* Drip pan made of aluminium alloy

Standards and Regulations

* Conformity Declaration of current Directive PED for Pressure Equipment

* Conformity Declaration of current Directive ATEX for Equipment used in Potentially explosive atmospheres

* Conformity Declaration of current Directive MACHINERY

* Customs Declaration of certification for Russia, Kazakhstan, Belarus, EAC certification.

* Standard API-ASTM-ANSI-TTMA.

Accessories

* Check valve

* Vacuum breaker valve

* Flow indicator

* Micro switch for indication of the position of loading valve

* Micro switch to indicate vertical position

* Micro switch to indicate rest position

* Mechanical lock “Hold Down” in working position

* Mechanical Park lock in rest position

* Overfill sensor with handle

* Up/Down pneumatic actuation

* Pneumatic Valve Actuation

* Pump start/stop buttons

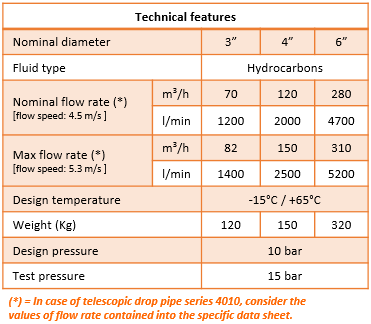

* Spring loaded Telescopic drop pipe

* Stand-post

.png)

Options on request

* Arm material options: all made of carbon steel, stainless steel AISI 304 or AISI 316.

* Seals in HNBR, FFKM, PTFE

* Left version

* Upward inlet flange

* Base swivel inlet flange PN16

* Split Type swivels: 3-pieces to facilitate maintenance.

* Compressed spring piston balancing

* Loading valve with “hold open” operation which closes automatically we the lever is released.

* Chrome plated loading valve inside for jet fuels.

* “T” deflector end-pipe in aluminium alloy

* Steam Jackets or electric tracing

* Special configurations for extreme temperatures (-60/+200 °C)

Standard documentation

* Declaration of conformity to regulations

* Declaration of material conformities and functional test (CCC)

* Operation and maintenance manual (MUM)

Documentation on request

* Welding book (WB):

• Welding map (WM)

• Welding qualification (PQR)

• Welding specifications (WPS)

• Welder qualification (WQ)

• Penetrant liquids test

• Radiographs of welding heads

* Materials specifications map (MIM):

• Certification 3.1 EN 10204 for steel

• Certification 2.2 EN 10204 for aluminium

* Quality complete plan (QCP):

• Welding dossier (WB)

• Materials identification map (MIM)

• Manufacturing plan